Hook into a row steel fiber machine

Classification :

PRODUCT DETAILS

Equipment name: end hook into row steel fiber machine

一 、 Used : production end hook into rowing steel fiber, output 10 hours 7-8 tons, end hook into row steel fiber products formed The rate is as high as 99%.

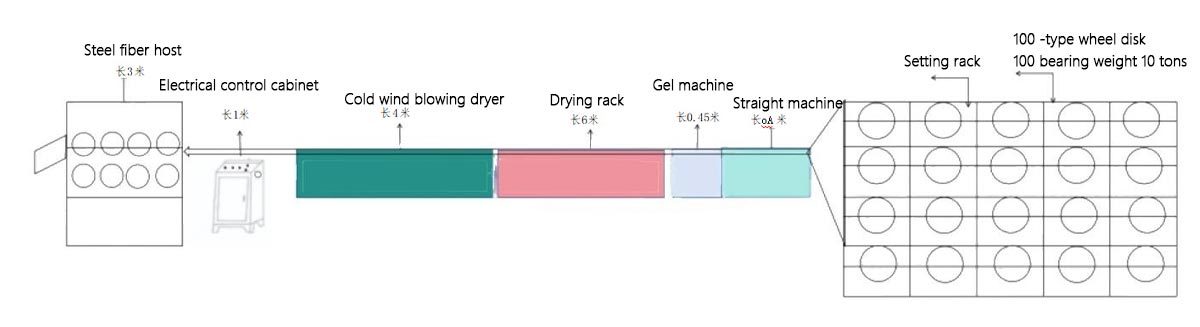

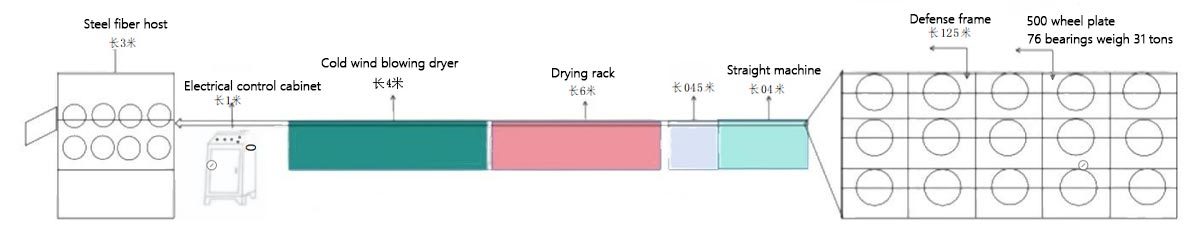

二 、 Equipment composition :

1. Steel fiber rolling head (300mmx90mm in diameter of the blade plate)

2. 2 specifications of automatic brakes and line frames;

1 type: 100 axes of the type 100 wheels, 6.5 meters long, and a weight of 10 tons.

The second type: 76 axes of the 500 wheels, 12.5 meters long, and a weight of 31 tons.

3. Straight machine (0.4 meters)

4. Glores (0.45 meters)

5. 2 specifications of drying frames;

1 type: drying rack (temperature can reach 500 ° C, stable, controllable) (3.2 meters long)

2nd type: Drying frame electromagnetic heating (6 meters long)

6. Cold wind blow dry rack (6 meters long)

7. Electric control cabinet (display)

8. Packaging vibrator

三. Manufacturing requirements:

1. Design speed: 80-100 meters/minute (50Hz), output 10 hours 6-8 tons;

2. Rolling machine power: 22kW-4;

3. Rolling wire diameter: 0.5-1.0mm carbon steel wire;

4. Transmission method: synchronous band+straight gear;

5. Bearing: Imported bearings;

6. Transmission gear: All transmission gear Luoz hardness is not less than 50 degrees;

7. Sending wheels: φ300, material: A3 material disc and polyurethane rubber wheel;

8. Rolling wheels: The knife plate φ300 × 90mm; the knife disc uses imported abrasive steel CR12MOV, Luoz hardness is 60 degrees;

The tool is a white steel knife. The normal production capacity of the knife is about 800 tons. It ensures that the feeding, molding, and cutting off are continuously continued to form.

9. Putting line disks: Putting lines, 1 size 0400*0197*340 (the size is provided by the buyer), the launch shelf is 100 axis, with a load of 10 tons; 2 feet 0500*0500, and the launch shelf is 76. Axis,

load -bearing 31 tons.

10. Parallers: more than 80 parallel lines;

11. Straight machine: neatly close, flat, tightly seamlessly arranged in the line;

12. Plastic machine: The upper glue area is precise, the coating is uniform, the glue speed can be adjusted and controlled, and the amount of glue is 1 tons of steel fiber dimension. 8kg;

13. Drying rack: single root power 2.2kW*18, total power 39.6kW; temperature can reach 500 ° C, the temperature is stable and the temperature and the temperature and the temperature

Adjustable and controlled; make appropriate insulation heating material manufacturing to ensure that fire, safety and reliability without leakage;

14. Cold blowing dry fans: 1 2.2kW;

15. Standard: a knife plate, containing knives. The blade is the imported abrasive steel CR12MOV; double -sided blade, a set of tools of about 800 tons of normal use of a set of tools;

16. Scientific, safe, efficient equipment design, fine work and beauty;

17. Painting: After rust -proof treatment of the equipment, paint paint is painted, and Party A provides color sample requirements;

四. Installation, debugging, warranty and technical support:

1. The equipment provided by the seller shall meet the technical requirements and meet the industry and national related technical standards. The equipment and its entire accessories must be a new product. After the manufacturing is completed, the buyer will try the car.

2. Installation and debugging: Within 3 working days after the contract is signed, the seller must provide foundation engineering and construction technical materials and construction drawings such as pipelines (including electrical, cooling water, compressed air) and other construction. After the equipment arrives, the seller sent people to the site to guide the installation and debugging to ensure that the equipment is put into production smoothly.

3. Warranty: 1 year of equipment warranty, free after -sales service, lifetime technical support, equipment upgrade. During the use of the device, if it is difficult to operate, the video guidance cannot be resolved, and you can on -site service for free. During the warranty period, if the electrical and motor is damaged due to quality problems, it should be replaced for free. Easy -to -loss parts of normal loss are not within the scope of protection. Normal loss consumables can be purchased by the seller's guidance to buyers themselves.

4. The seller must provide the size of the edible consumable parts such as transmission belts, blades, blade, and pressure wheels in the equipment to guide the buyer to equip the later use process. The seller is responsible for the training of the buyer's operators and maintenance personnel to ensure that the buyer can operate the equipment correctly and put into operation normally, including: basic principles, operations, maintenance, maintenance, and the configuration, installation, maintenance, maintenance of equipment is easy to consume.

The appearance of the end hook into a row steel fiber machine:

PACKAGES

CUSTOMER VISIT

Customer visit

Customer visit

Customer visit

Customer visit

Customer visit

Customer visit

FACTORY WORKSHOP

Factory building

Factory building

Factory building

Factory building

Factory building

Factory building

FAQ

Q: What are applications of our steel fiber?

Q: What kinds of fibers can you supply?

Q: When can I receive my products?

Q5: What is your terms of payment ?

Q4:How do you check all the goods in the production line?

Q3: How do you make our business long-term and good relationship?

RELATED PRODUCTS

GET A FREE QUOTE